Resource Type: Press Releases

Tag: Fulfilment

PRESS RELEASE

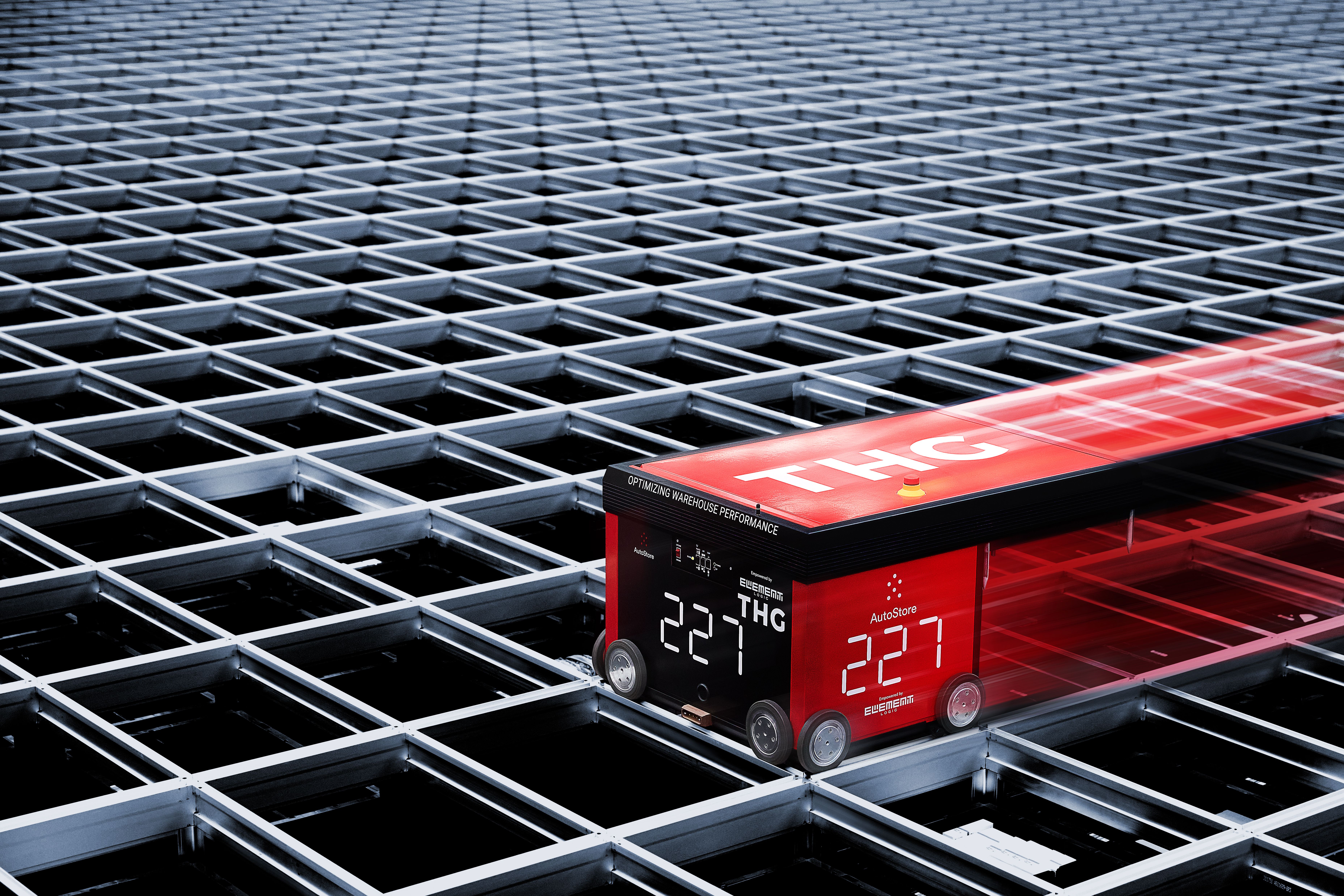

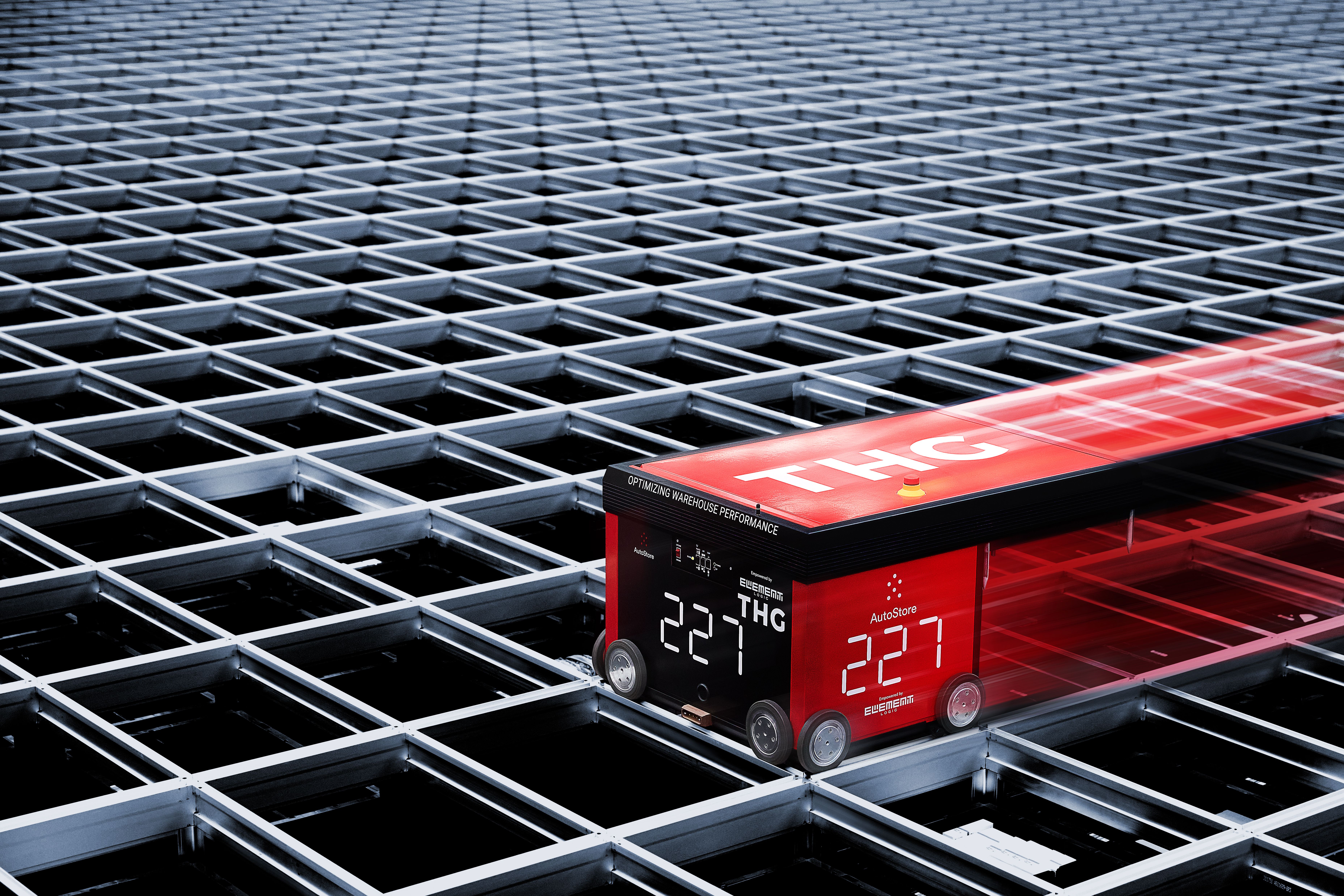

THG Fulfil deploys advanced AutoStore system at Omega warehouse

New 120,000-bin installation in Warrington delivers 25% performance uplift and industry-leading 1am NDD cut-off capability

July 22, 2025

Resource Type: Press Releases

PRESS RELEASE

THG Fulfil deploys advanced AutoStore system at Omega warehouse

New 120,000-bin installation in Warrington delivers 25% performance uplift and industry-leading 1am NDD cut-off capability

July 22, 2025

World-class fulfilment and courier management solution, THG Fulfil, today announces the launch of its cutting-edge AutoStore installation at its Omega warehouse in Warrington. This substantial deployment represents a significant advancement in automated fulfilment capabilities and reinforces THG Fulfil’s position as the only AutoStore distributor offering Robots as a Service (RaaS).

RaaS allows customers to pay a monthly fee that covers the grid, ports, and robots. It provides a more flexible, scalable approach to automation, allowing brands to access cutting-edge technology and benefit from increased efficiency without the high upfront capital outlay historically required.

The new AutoStore system features impressive specifications including 120,000 bins, 100 R5 Pro robots, 20 outbound ports, and 6 inbound ports. R5 Pro robots are energy efficient and equipped with rapid charging, enabling a significant reduction in charging infrastructure allowing for a robot count reduction of up to 15% compared to standard R5 robot grids.

The installation is projected to deliver a 25% performance uplift, compared to THG Fulfil’s existing AutoStore build at its Icon 2 warehouse in Manchester, significantly enhancing operational efficiency and throughput capacity.

Setting THG Fulfil apart from traditional distributors, the business has maintained complete ownership and control of the entire implementation process. THG Fulfil serves as the principal contractor for comprehensive infrastructure delivery, encompassing all flooring works, suspended ceilings, sprinkler systems, electrical installations and mechanical engineering requirements. Through partnerships with approved contractors specialising in enabling works, THG Fulfil’s dedicated projects team delivers the complete suite of services required to accelerate investment deployment and operational readiness.

This holistic approach includes proprietary development of the Warehouse Control System (WCS), infrastructure enablement, data management, system commissioning, software deployment and WCS implementation, all executed in-house without third-party dependencies. Crucially, THG Fulfil stands as the only AutoStore distributor globally that is also an active end user of the technology, operating the highest output D2C (direct-to-consumer) fulfilment facility among AutoStore deployments worldwide.

Tom Killeen, COO, THG Ingenuity said: "This new AutoStore installation is testament to our continued investment in new technology. We aren't just automation distributors; we are the only automation distributors who are also end users. We see ourselves as experts who understand the operational pain points and deliver end-to-end solutions that drive measurable business outcomes. Our RaaS approach fundamentally changes how brands can access world-class automation. By combining our technical expertise with flexible commercial models, we’re democratising access to the same automation capabilities used by the world’s largest ecommerce operations. Our unique position as both distributor and operator means we deliver solutions proven at the highest performance levels.”

THG Fulfil’s capabilities extend beyond automation hardware to include third-party logistics (3PL) capabilities incorporating fulfilment, courier management, and warehouse storage solutions. For more information on THG Fulfil's solutions, visit thgingenuity.com/fulfillment.